Top Suppliers Hamburger/Burger Box, Lunch Paper Box, Kfc Popcorn Chip Box, Fast Food Box, Take Away Box Forming Machine, Paper Carton Box Erecting Machine

We insist on offering good quality production with good small business concept, honest income plus the ideal and fast service. it will bring you not only the premium quality solution and huge profit, but by far the most significant should be to occupy the endless market for Top Suppliers Hamburger/Burger Box, Lunch Paper Box, Kfc Popcorn Chip Box, Fast Food Box, Take Away Box Forming Machine, Paper Carton Box Erecting Machine, sincerity and strength ,constantly preserve approved great quanlity ,welcome to our factoty for check out and instruction and organization.

We insist on offering good quality production with good small business concept, honest income plus the ideal and fast service. it will bring you not only the premium quality solution and huge profit, but by far the most significant should be to occupy the endless market for China Burger Box Making Machine and Food Box Machine, Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!

Features of patty/nugget production line

1. The CXJ-100 automatic hamburger patty forming machine can automatically complete the filling, forming, output and other processes. Products of different shapes (round, square, oval, triangle, heart and other special shapes) can be produced by changing different molds.

2. The NJJ-200 battering machine can automatically complete the battering process of the product, and coat the product with a layer of slurry. The battered product is air-drenched to avoid excessive slurry entering the next process. Thin pulp and thick pulp are available. The battering machine is used in conjunction with the automatic meat pie forming machine, or it can be used alone.

3. The crumbs breading machine automatically completes the breading process of the product, both fine and coarse. Spread bread crumbs evenly on chicken, beef, pork, fish and shrimp and other products.

Applicable raw materials

Meat (meat, beef, lamb, pork, etc.);

Aquatic products (fish, shrimp, etc.);

Vegetables (potatoes, squash, green beans, etc.);

Cheeses and their mixtures.

Detail drawing

Burger patty maker

NJJ-200battering machine

Patty production line

Applicable products

The production line can produce hamburger patties, chicken McNuggets, potato cakes, pumpkin pie skewers, chicken tenders and other products popular in the market. It is an ideal meat (vegetable) production line for fast food restaurants, distribution centers and food factories.

Instructions of burger patty former

1. Choose a flat floor, put the patty forming machine firmly, and pull the chassis legs apart to make the machine panel easy to observe.

2. Insert the plug on the hand-held sensor head of the patty forming machine into the socket on the panel and tighten it. Note the positioning gap.

3. Insert one end of the plug of the power cord into the socket on the rear panel of the chassis, and the other end into the power supply socket. Please be sure to use a single-phase three-wire power supply.

4. Turn on the main power switch on the rear panel of the chassis, press the power switch key on the panel, and wait until the green indicator light of “ready” is on, the machine can work.

5. Press and hold the “Setting button” key, and set it to a suitable value, generally between 0.5-2.0 seconds.

6. Press the start button to start working.

Specifications

| Model | Power | Belt Width | Weight | Capacity | Dimension |

| CXJ-100 | 0.55KW | 100mm | 100KG | 35pcs/min | 860x600x1400mm |

| NJJ-200 | 0.62KW | 200mm | 100KG | lOOkg/h | 1400x550x1250mm |

| SXJ-200 | 0.86KW | 200mm | 150KG | lOOkg/h | 1720x650x1400mm |

Hamburger patty/nugget production line Video

Product display

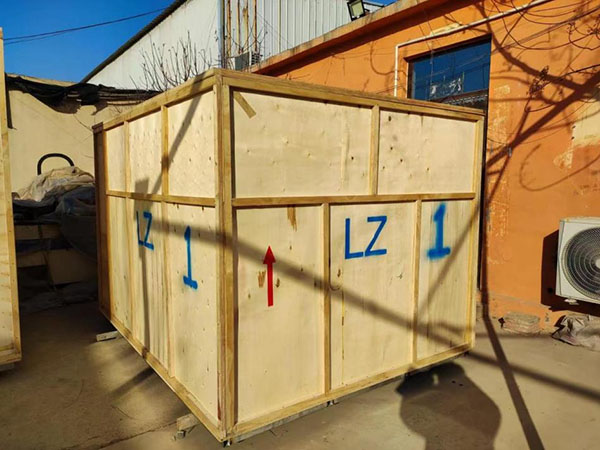

Delivery show

We insist on offering good quality production with good small business concept, honest income plus the ideal and fast service. it will bring you not only the premium quality solution and huge profit, but by far the most significant should be to occupy the endless market for Top Suppliers Hamburger/Burger Box, Lunch Paper Box, Kfc Popcorn Chip Box, Fast Food Box, Take Away Box Forming Machine, Paper Carton Box Erecting Machine, sincerity and strength ,constantly preserve approved great quanlity ,welcome to our factoty for check out and instruction and organization.

Top Suppliers China Burger Box Making Machine and Food Box Machine, Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!