Special Design for Meat Strip Cutting Machine/Meat Slicer Cutter/Meat Slicer and Grinder Meat Processing Machinery

All we do is usually connected with our tenet ” Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Special Design for Meat Strip Cutting Machine/Meat Slicer Cutter/Meat Slicer and Grinder Meat Processing Machinery, If you are fascinated in almost any of our solutions or would want to discuss a custom-made order, remember to really feel absolutely free to contact us.

All we do is usually connected with our tenet ” Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Meat Cutter and Commercial Meat Slicer, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

Features of chicken breast slicing machine

1.Uniform cutting thickness, multi-piece cutting, high efficiency;

2.Imported modular mesh belt, high service life;

3.Waterproof design, smoother cutting surface;

4.Accurate cutting width, the narrowest can reach 5mm, multi-piece cutting, high efficiency;

5.It can also be designed to cut products with different width combinations according to production needs;

6.The width of the cut product can be adjusted by changing the knife holder or knife spacer;

7.The knife holder, input mesh belt, and output mesh belt are detachable for easy cleaning;

8.The structural design of the spray makes the cut meat section smooth.

Applicable situation

1.According to the nominal voltage on the nameplate, the power switch with leakage protector must be well connected to the ground wire.

2.Turn on the switch, and the meat will be smoothly transported from the conveyor belt to cut into strips once, and cut into blocks for the second time.

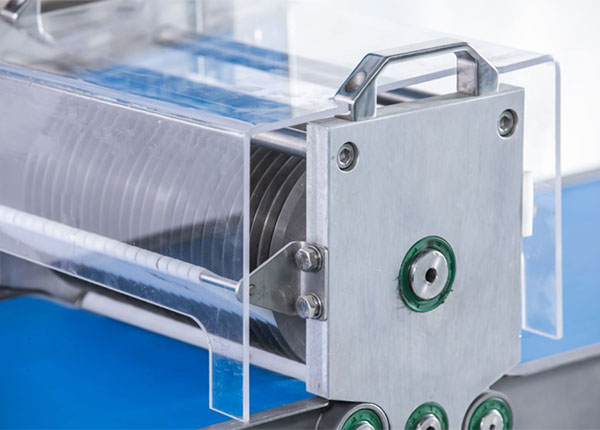

Detail drawing

300 stripe cutter

Blade

Stripe cutter controlpanel

How to start the meat stripe cutter machine

1.300 Meat stripe cutter machine is suitable for poultry, fish, shrimp, beef, mutton,pork etc.

2.This machine can make chicken fingers, tenders, popcorn, fillet etc.

The cleaning method

1.After cutting off the power supply, to disassemble the conveyor belt, you need to unscrew the screws on the side. The knife is easy to disassemble and easy to clean.

2. For the dismantled conveyor belt, the blades should be rinsed with water or soaked in water. The cleaning of the blade is particularly important, and water can be used to repeatedly rinse the blade from the feeding port.

Specifications

| Model | QTJ300 |

| Belt Width | 300mm |

| Belt Speed | 3-18m/min Adjustable |

| Cutting Thickness | 5-45mm(70mm customized) |

| Cutting Capacity | 300-500kg/h |

| Raw Material Width | 300mm |

| Height(input/output) | 1050±50mm |

| Power | 1.5KW |

| Dimension | 1500x640x1000mm |

Meat Stripe Cutter Machine Video

Product Display

Delivery show

All we do is usually connected with our tenet ” Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for Special Design for Meat Strip Cutting Machine/Meat Slicer Cutter/Meat Slicer and Grinder Meat Processing Machinery, If you are fascinated in almost any of our solutions or would want to discuss a custom-made order, remember to really feel absolutely free to contact us.

Special Design for Meat Cutter and Commercial Meat Slicer, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.